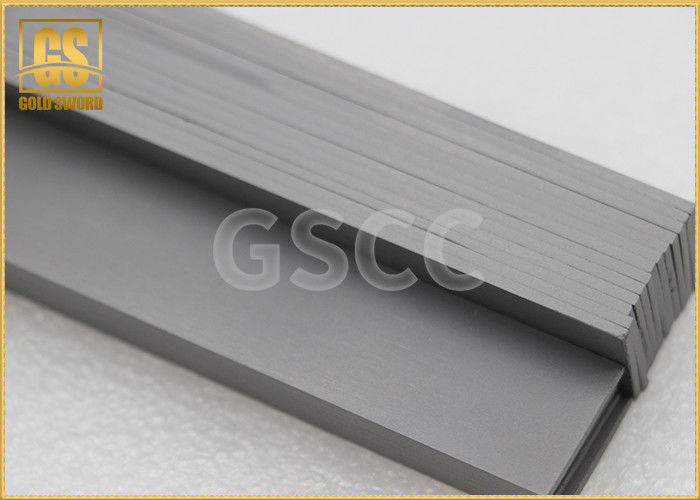

Multipurpose Tungsten Carbide Blade K30 Fine Machining 200 - 500 M / Min Speed

Product Details:

| Place of Origin: | Zhuzhou,Hunan,China(mainland) |

| Brand Name: | Gold Sword |

Payment & Shipping Terms:

| Price: | Negotiable |

|---|---|

| Packaging Details: | Carton packaging 15 kg per carton |

| Delivery Time: | 25 days |

| Payment Terms: | TT |

|

Detail Information |

|||

| Size: | OEM Acceptable | Material: | Tungsten Carbide |

|---|---|---|---|

| Surface: | Polished | Using Method: | POT And EOT |

| High Light: | tungsten carbide tipped saw blade,tungsten carbide multi tool blades |

||

Product Description

Cemented carbide has high hardness, strength, wear resistance and corrosion resistance. It is known as “industrial teeth” and is used in the manufacture of cutting tools, cutting tools, cobalt tools and wear parts. It is widely used in military and aerospace. In the fields of machining, metallurgy, oil drilling, mining tools, electronic communication, construction, etc., with the development of downstream industries, the demand for hard alloys is increasing. And the future of high-tech weaponry equipment manufacturing, advances in cutting-edge science and technology, and the rapid development of nuclear energy will greatly increase the demand for high-tech content and high-quality stability of cemented carbide products.

Classification

Drag blades: used in non-powered tools such as UCT, KCT, VCT, SCT, C2

Particularly suitable for Foils, Paper, Thin folding carton, PVC,Plastic ,Carpet ,Light foam core etc.

Oscillating blades: used in EOT / POT oscillating tools.

Recommended materials: Folding carton, Gasket materials, Foam, Leather,Rubber, Felt,Woven , Textiles, Plastic etc.

Rotary blade: decagonal (ten-sided) blades for DRT / PRT tools.

Recommended for breathable materials such as textile, carbon fibre, glass fibre, etc.

Coating blade mark and use recommended

| ISO classification | Mark | uses | Cutting speed(m/min) |

| P | YBC151 | High wear-resistant matrix and ultra-thick composite coating for steel finishing. | 180-460 |

| YBC152 | 220-550 | ||

| YBC251 | A tough base with good edge safety and a coating of MT-TiCN for semi-finishing of steel. | 160-440 | |

| YBC252 | 180-480 | ||

| YBC351 | The highly plastic matrix and the composite thick coating are suitable for roughing of steel. | 130-380 | |

| M | YBM151 | Suitable for finishing and semi-finishing of stainless steel. | 110-280 |

| YBM251 | Suitable for semi-finishing of stainless steel. | ||

| YBM351 | Suitable for rough finishing of stainless steel. | ||

| K | YBD052 | The chemical ultra-thick coating combines with a hard matrix to provide excellent wear resistance in high-speed dry cutting of grey cast iron. | 200-500 |

| YBD102 | Chemically coated grade for high speed cutting of ball cast iron. | 200-480 | |

| YBD152 | Good anti-flaking, suitable formedium- and high-speed turning in cast iron, and can withstand slight interrupted cutting at medium speed. | 180-450 | |

| YBD252 | Suitable for turning in medium and low speed wet milling and intermittent conditions of cast iron with toughness requirements. | 150-380 |

Recommended cutting amount ( B04 )

| Raw material | processing method | Mark | Cutting speed(m/min) | |

| P | steel | c | YBC151 | 180-460 |

| YBC152 | 220-500 | |||

| semi finishmachining | YBC251 | 160-440 | ||

| YBC252 | 180-480 | |||

| rough finish machining | YBC351 | 130-380 | ||

| M | stainless steel |

fine machining, semi finish machining, rough finish machining |

YBM151 YBM251 |

110-280 |

| K | cast iron | fine machining | YBD052 | 200-500 |

| YBD102 | 200-480 | |||

| semi finish machining | YBD151 | 180-450 | ||

| YBD152 | 190-450 | |||

| rough finish machining | YBD252 |

150-380 |

||