High Hardness YG15 YG20 Finished Tungsten Carbide Plate

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | 100*100*(3-20),100*200*(3-20),200*200*20.ect. |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | pcs |

| Packaging Details: | boxes, carton |

| Delivery Time: | 7-10 days |

| Payment Terms: | FOB, L/C, T/T |

| Supply Ability: | 10000pcs/month |

|

Detail Information |

|||

| Material: | 100% Virgin Tungsten Carbide,Original Tungsten Carbide Material,WC+CO,100% Virgin Raw Material,100% Original Carbide | Chemical Composition: | Tungsten,WC+Co,Ni.steel,WC + Co,ect. |

|---|---|---|---|

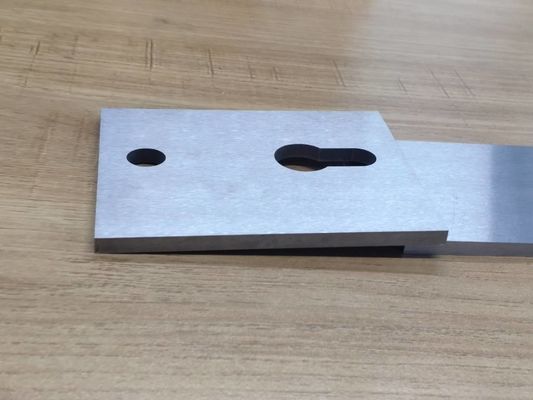

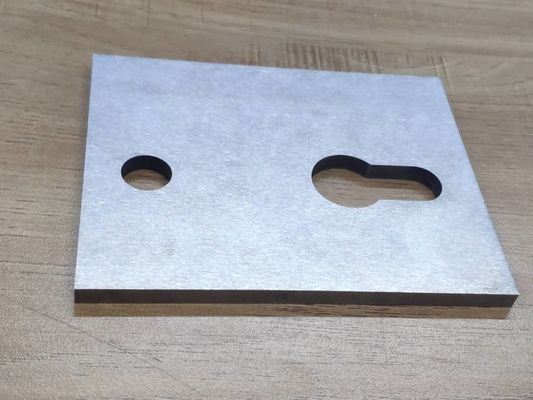

| Advantage: | 15 Years Experience In Making Carbide Tungsten Cobalt Insert,Wear Resistant Superior,Durable,Manufactuer | Commodity Name: | YG15 YG20 High Hardness Tungsten Carbide Square Bar,plates For Making Plane Cutters,tungsten Carbide Draw Plate |

| Service: | ODM OEM,customized Available | Physical Performance: | High Bending Strength,wear Resistance,high Strength And Hardness Wear Resistance,high Hardness |

| Business Type: | Manufactuer Since 1998,Manufacturer | ||

| High Light: | YG20 Tungsten Carbide Plate,YG15 Tungsten Carbide Plate,YG20 Finished Carbide Plate |

||

Product Description

Long Life Cutting Tools Tungsten Carbide Sheet With High Wear Resistance

Carbide Wear Parts is a hard material composed of a metal matrix composite where carbide particles act as the aggregate and a metallic binder serves as the matrix. It is one of the most successful composite engineering materials ever produced. Its unique combination of strength, hardness and toughness satisfies the most demanding applications.

Tungsten carbide is used in machining tough materials such as cast iron or steel, as well as in situations where other tools would wear away, such as mining tools and wear parts. Most of the time, carbide will leave a better finish on the part,and allow faster machining. Carbide tools can also withstand higher temperatures than standard high speed steel tools

|

GSGrade |

ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | High toughness, easy to be brazed without heat preservation. Suitable for rosewood, solid wood, pinewood, and other wood with a lot stammer. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

| YN15 | K40 | 14-14.2 | 85-86 | 1700-1900 |

Medium |

Mainly used for stamping moulds and ceramic die of electronic components, petroleum machinery corrosion resistant instrument, without magnetic.

|

| SK40S | K10 | 14.5 | 91 | 3000-3200 |

Fine |

On the basis of high bending strength, the hardness and wear resistance are improved, and the edge is dense, which is beneficial to the smoothness of processing

|

Zhuzhou Gold Sword Cemented Carbide Co., Ltd. Located In Zhuzhou City, Hunan Province, Which Is The Largest Cemented Carbide Production And Sales Base In China. Our Main Products Are Carbide Strips, Carbide STB Bars, Carbide Sand Breaking Strips, Carbide ASA Brazing Tips, Carbide Cold Heading Dies And Carbide Rods. Our Professional And Technical Personnel All Have Above 15 Years Of Cemented Carbide Production Experience, The Rich Experience Can Provide Our Customers Of High-Quality Products And Thoughtful Technical Support, And Continuous Improvement To Meet Customer Needs.

The "stability" and "consistency" of products are the focus of our quality control

The company uses advanced testing equipment to continuously formulate and improve the quality control system.

Strictly train a quality control technician with outstanding skills,

According to the raw material monitoring, process production and final inspection,

The whole process is strictly monitored in accordance with international quality control system standards;

All-round inspection of products from chemical composition, organization structure, physical properties, appearance size, etc.

Through strict monitoring of the process, optimized control of production details, and strict selection of finished products,

In line with the "customer satisfaction" standard, the product quality is stable and reliable,so as to provide customers with high-performance quality products.

Based on the damands of customers , for different industries, different materials and different working conditions, provide customers with accurate service and solutions of products, and provide high cost-effective products, to keep the promises of our customers, and Timely provide the professional technical services.