Cryogenic treatment Tungsten Carbide Strips 100% Virgin Raw Material

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | 100*50*2.5,120*130*20,180*80*3 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | kilogramme/pcs |

| Packaging Details: | In one carton or as your wish, plastic box, Neutral packing or per customers' request |

| Delivery Time: | 15-30 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 9T/ton |

|

Detail Information |

|||

| Grade: | YG6X/YG6/YG8/YG15/YG20/YG25/YS2T Etc. | Material: | 100% Virgin Raw Material,Tungsten Carbide WC+Co |

|---|---|---|---|

| Additional Processing: | Cryogenic Treatment | Additional Detect: | Flaw Detection Processing |

| High Light: | Cryogenic Treatment Tungsten Carbide Strips,100% Virgin Tungsten Carbide Strips,YG20 Tungsten Carbide Strips |

||

Product Description

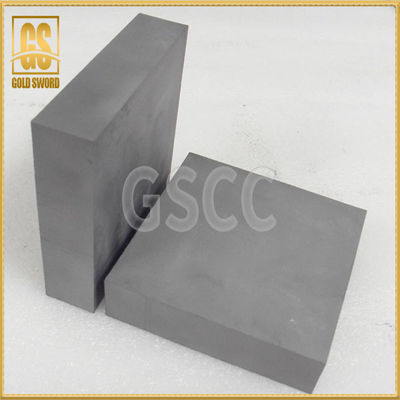

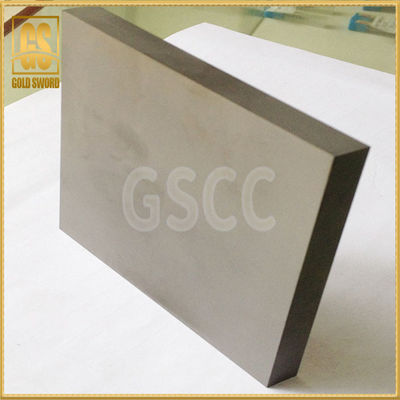

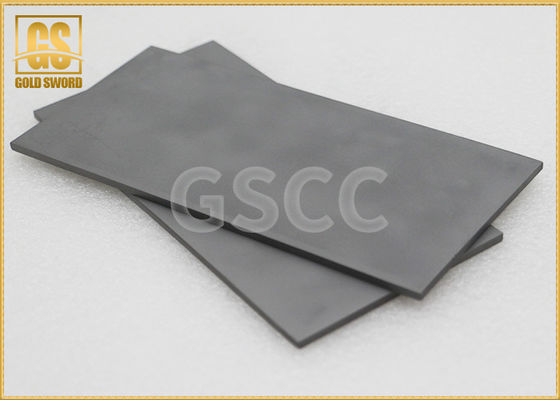

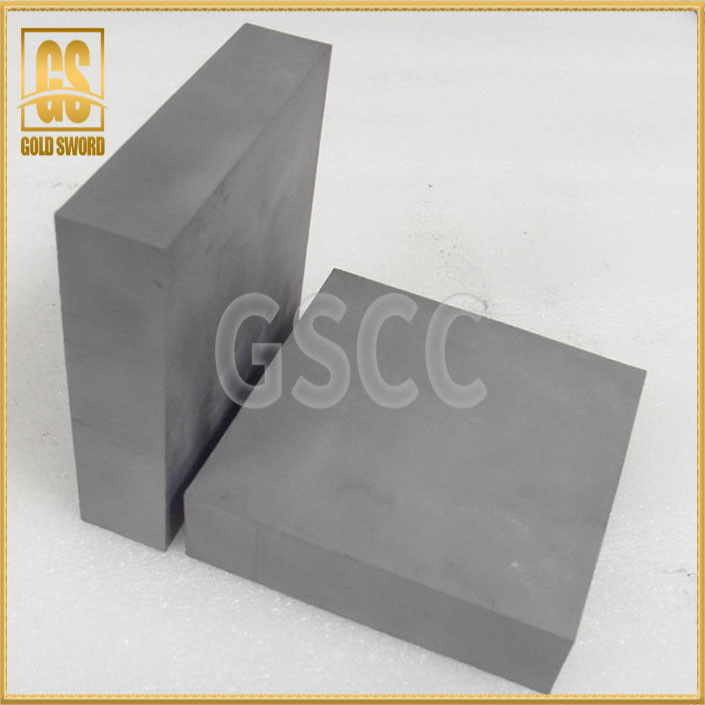

the plates we produce are denser, more uniform in size, and better in flatness.

Features of tungsten carbide sheet:

1. The purity of the raw materials is more than 99.5%, the impurity content is very small, and the physical properties of the board are more stable;

2. Using spray drying technology, the materials are protected by high-purity nitrogen under fully sealed conditions, which effectively reduces the possibility of oxygenation during the preparation of the mixture, and the purity is better, and the materials are not easy to be dirty;

3. Uniform density of cemented carbide plates: it is pressed by a 300Mpa isostatic press, which effectively prevents the occurrence of pressing defects, and the density of the plate blanks is more uniform;

4. The compactness of the plate is excellent, and the strength and hardness indicators are excellent: the ship low-pressure sintering technology is used to effectively eliminate the pores in the plate and the quality is more stable.

5. Cryogenic treatment technology is used to improve the internal metallographic structure of the plate, and the internal stress can also be greatly eliminated, avoiding the occurrence of cracks in the cutting and forming process of the plate.

The main purpose:

Tungsten steel sheet has excellent hardness, high hardness, good wear resistance, high elastic modulus, high compressive strength, good chemical stability (acid, alkali, high temperature oxidation resistance), low impact toughness, low expansion coefficient, The characteristics of thermal conductivity and electrical conductivity similar to those of iron and its alloys, due to the great advantages of tungsten steel turning tools, have been quickly promoted in the industry. In just 50 years, due to the use of tungsten steel turning tools, the metal cutting speed has increased two hundred times, from ten meters per minute to more than two kilometers. The heat-resistant tungsten steel still maintains good elasticity and mechanical strength, and is generally used for thicker cutting, intermittent cutting and poor parts clamping. After coating, the effect is better, and it can be processed to various materials of HRC50°. Corresponding to general tungsten steel, it has 1 to 2 times the service life and excellent impact resistance.

Products pictures

![]()

![]()

Carbide sheet grade and application.

| GSGrade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Hardness (HRA) | Grain Size | Performance & Application Recommended |

| YG8D | 14.9 | 90 | 2150 | 90 | fine | Suitable for hardwood, raw wood, aluminum profile, copper rod and cast iron processing. |

| YG8 | 14.7 | 92 | 2320 | 92 | Medium | It is suitable for making forming knives and wear-resistant consumable parts. |

| YG6A | 14.9 | 89.5 | 1860 | 89.5 | Coarse | It is suitable for making forming knives and wear-resistant consumable parts. |

| YG15 | 14.5 | 87.5 | 2500 | 87.5 | Ultrafine | Suitable for making stamping dies, wear-resistant parts. |

| YG20 | 13.5 | 85.5 | 2800 | 85.5 | Coarse | Suitable for making precision grinding grade stamping dies. |

| YS2T | 14.5 | 92 | 2350 | 92 | fine | Suitable for processing high temperature alloy, stainless steel, high manganese steel and other materials. |

Production process:

Pulverizing → formula according to application requirements → wet milling → mixing → crushing → drying → sieving → adding forming agent → re-drying → sieving to obtain a mixture → granulating → pressing → forming → sintering → forming (blank) →Flaw inspection→Packing→Warehousing.

Super long service life

The high hardness, high strength and other properties of cemented carbide can be 50 to 100 times longer than ordinary alloys in use, eliminating the time and labor cost of frequent product replacement, which greatly improves Improve production efficiency and save a lot of production costs for enterprises.