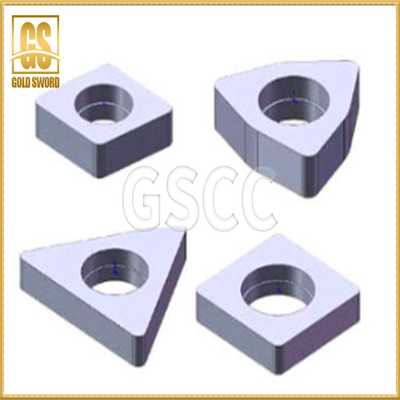

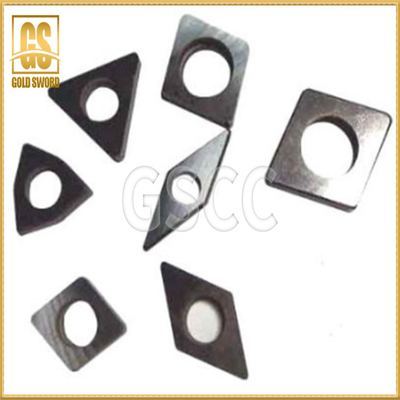

blade cutting knife Coated high-speed steel tools, coated carbide tools for digital cutter and CNC

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | kilogramme/pcs |

| Packaging Details: | paper boxes, wooden boxes、carton |

| Delivery Time: | 15~20 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 50000pcs/month |

|

Detail Information |

|||

| Size: | OEM Acceptable | Material: | Tungsten Carbide |

|---|---|---|---|

| Insert: | Coated, Coating Insert, | Feature: | Good Mechanical And Cutting Performance |

| Usage: | CNC,machining Operation | Strong Versatility: | Coated Tools Have Wide Versatility, And The Processing Range Is Significantly Expanded. One Coated Tool Can Replace Several Non-coated Tools. |

| High Light: | tungsten carbide tipped saw blade,carbide cutting blades |

||

Product Description

Excellent material to produce Plotter / Digital cutters' blades knives.

High hardness, super cutting quality, durable sharpness, long lifespan.

Competitive price, well accepted by our customers.

Availability in stock, blades can be sent to our customers in a short time.

Carbide blades have a significantly higher life expectancy than high speed steel blades.

Made from 100% virgin raw material.

Ultrafine grain sizes

Produced with advanced equipments and process

All products go through in process and final inspection

Stable and continuous production ability

Classification

Drag blades: used in non-powered tools such as UCT, KCT, VCT, SCT, C2

Particularly suitable for Foils, Paper, Thin folding carton, PVC,Plastic ,Carpet ,Light foam core etc.

Oscillating blades: used in EOT / POT oscillating tools.

Recommended materials: Folding carton, Gasket materials, Foam, Leather,Rubber, Felt,Woven , Textiles, Plastic etc.

Rotary blade: decagonal (ten-sided) blades for DRT / PRT tools.

Recommended for breathable materials such as textile, carbon fibre, glass fibre, etc

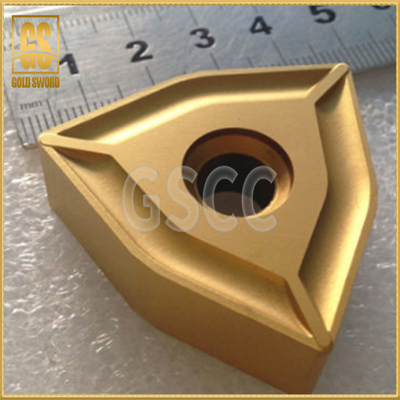

Coated tool is to coat a thin layer of refractory metal or non-metal compound with good wear resistance on the surface of cemented carbide or high-speed steel (HSS) with good strength and toughness. It is prepared on the blades of superhard materials such as ceramics, diamond and cubic boron nitride. The coating acts as a chemical barrier and thermal barrier, reducing the diffusion and chemical reaction between the tool and the workpiece, thereby reducing the wear of the substrate. Coated tools have the characteristics of high surface hardness, good wear resistance, stable chemical properties, heat resistance and oxidation resistance, low friction coefficient and low thermal conductivity. During cutting, the service life of uncoated tools can be increased by more than 3 to 5 times, which improves cutting The speed is 20%~70%, the machining accuracy is improved by 0.5~1 level, and the tool consumption cost is reduced by 20%~50%.

Performance characteristics of the coated blades

1.Good mechanical and cutting performance: The coated tool combines the excellent properties of the base material and the coating material, which not only maintains the good toughness of the base...

2. Strong versatility: Coated tools have wide versatility, and the processing range is significantly expanded. One coated tool can replace several non-coated tools.

3. Coating thickness: As the coating thickness increases, the tool life will increase, but when the coating thickness reaches saturation, the tool life will no longer increase significantly...

4. Regrindability: poor regrindability of coated blades, complex coating equipment, high process requirements, and long coating time.

Coating blade mark and use recommended

| ISO classification | Mark | uses | Cutting speed(m/min) |

| P | YBC151 | High wear-resistant matrix and ultra-thick composite coating for steel finishing. | 180-460 |

| YBC152 | 220-550 | ||

| YBC251 | A tough base with good edge safety and a coating of MT-TiCN for semi-finishing of steel. | 160-440 | |

| YBC252 | 180-480 | ||

| YBC351 | The highly plastic matrix and the composite thick coating are suitable for roughing of steel. | 130-380 | |

| M | YBM151 | Suitable for finishing and semi-finishing of stainless steel. | 110-280 |

| YBM251 | Suitable for semi-finishing of stainless steel. | ||

| YBM351 | Suitable for rough finishing of stainless steel. | ||

| K | YBD052 | The chemical ultra-thick coating combines with a hard matrix to provide excellent wear resistance in high-speed dry cutting of grey cast iron. | 200-500 |

| YBD102 | Chemically coated grade for high speed cutting of ball cast iron. | 200-480 | |

| YBD152 | Good anti-flaking, suitable formedium- and high-speed turning in cast iron, and can withstand slight interrupted cutting at medium speed. | 180-450 | |

| YBD252 | Suitable for turning in medium and low speed wet milling and intermittent conditions of cast iron with toughness requirements. | 150-380 |

Recommended cutting amount ( B04 )

| Raw material | processing method | Mark | Cutting speed(m/min) | |

| P | steel | c | YBC151 | 180-460 |

| YBC152 | 220-500 | |||

| semi finishmachining | YBC251 | 160-440 | ||

| YBC252 | 180-480 | |||

| rough finish machining | YBC351 | 130-380 | ||

| M | stainless steel |

fine machining, semi finish machining, rough finish machining |

YBM151 YBM251 |

110-280 |

| K | cast iron | fine machining | YBD052 | 200-500 |

| YBD102 | 200-480 | |||

| semi finish machining | YBD151 | 180-450 | ||

| YBD152 | 190-450 | |||

| rough finish machining | YBD252 |

150-380 |

||

![]()

![]()

![]()