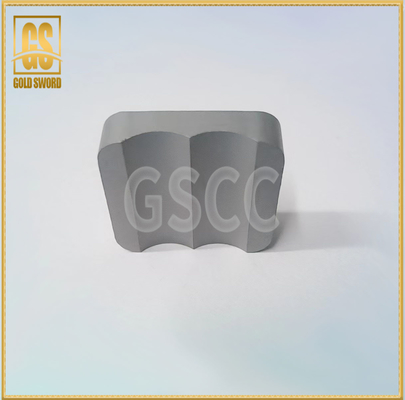

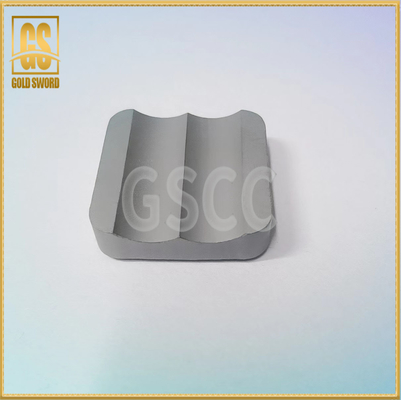

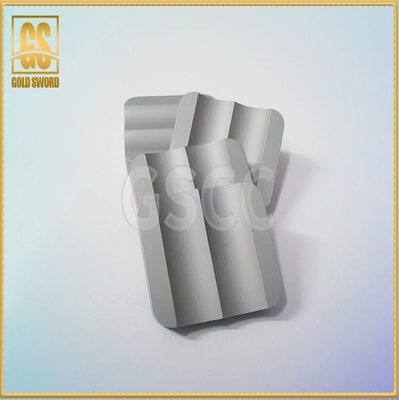

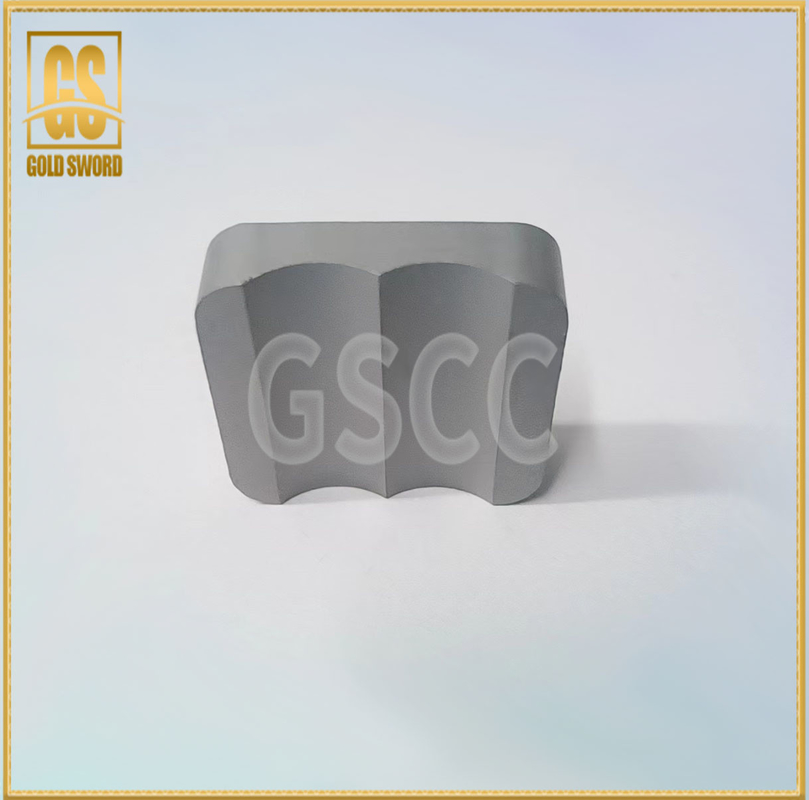

Special Shaped Double Grooved Square Insert Wear Resistant Customized

Product Details:

| Place of Origin: | ZHUZHOU |

| Brand Name: | Gold sword |

| Certification: | ISO9001 |

| Model Number: | can be customized |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | kilogramme/pcs/length |

| Packaging Details: | In one carton or as your wish, plastic box, Neutral packing or per customers' request |

| Delivery Time: | 15~20 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 30000pcs/month |

|

Detail Information |

|||

| Shape: | Strip | Shape: | Strip |

|---|---|---|---|

| Shape: | Strip | Material: | Tungsten Carbide |

| Specification: | Within 1 Meter, Within 100 Within Width, Within 20 Thickness, Any Size | Specification: | Within 1 Meter, Within 100 Within Width, Within 20 Thickness, Any Size |

| Precision: | Metric Accuracy Grade,μm | Product Detect: | Two-dimensional |

| Application: | Cutting Tools, Wear Parts, Mining Tools, Etc. | Coating: | TiCN, TiN, TiAlN, AlTiN, TiAlCrN, CrN, DLC |

| Grades: | YG6, YG8, YG15, YG20, YG30, YG20C, YG30C, YG40C, YG50C, YG60C, YG70C, YG80C | Hardness: | HRA90-92 |

| MOQ: | 1 Piece | Packaging: | Carton Box |

| Packaging: | Carton Box | Size: | Customized |

| Surface: | Polished | Tolerance: | ±0.01mm |

| High Light: | Customized Double Grooved Square Insert,Customized Double Grooved Square Insert,ISO9001 Double Grooved Insert |

||

Product Description

Special Shaped Double Grooved Square Insert With Good Wear-Resistant, Customized Blade.

carbide describe

What is tungsten carbide fact?

Tungsten is a heavy, gray metal with bluish overtones. When mixed with black carbon, tungsten carbide is created. Tungsten carbide facts are an inorganic chemical compound containing equal parts of tungsten and carbon atoms. The cobalt in tungsten carbide is the element of most concern. Tungsten carbide fact often contains nickel and chromium, which can also cause asthma. In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, other tools and instruments, and jewelry.

Chemical Properties of Tungsten Carbide Fact

At high temperatures WC decomposes to tungsten and carbon and this can occur during high-temperature thermal spray, e.g., in high velocity oxygen fuel (HVOF) and high energy plasma (HEP) methods.

Oxidation of WC starts at 500–600 °C. It is resistant to acids and is only attacked by hydrofluoric acid/nitric acid (HF/HNO3) mixtures above room temperature. It reacts with fluorine gas at room temperature and chlorine above 400 °C (752 °F) and is unreactive to dry H2 up to its melting point. WC dissolves readily in diluted hydrogen peroxide.

Physical Properties of Tungsten Carbide Fact

Tungsten carbide is high melting, 2,870 °C (5,200 °F), extremely hard (~9 Mohs scale, 1700–2400 Vickers number) with low electrical resistivity (~2×10−7 Ohm•m), comparable with that of some metals. Tungsten carbide is a much more versatile material than most other metals. It is four times as hard as titanium and twice as hard as steel. Tungsten carbide is much more heat resistant than both metals as well.

Tungsten carbide fact has a variety of uses due to its unique physical properties. Its molecular formula is WC, and it is very similar in nature to titanium carbide. Since it does contain two different elements, it is classified as a chemical compound. Sometimes, tungsten carbide fact is just referred to as carbide in everyday speech.

Tungsten carbide fact is a compound made of the elements tungsten and carbon. Its density makes it highly valuable in the military, and the mining and manufacturing industries. Since its creation, tungsten carbide has even been used to make wedding bands.

Hardness of Tungsten Carbide Fact

Tungsten carbide fact measures a nine on Moh's hardness scale, meaning it is about as hard as corundum, but not as hard as diamond. In order to polish or finish an item made of tungsten carbide fac, a diamond must be used because any other metal or mineral would crack and break. Only a diamond is hard enough to be able to scratch tungsten carbide. Its density also surpasses the density of titanium.

Composition and Properties of Tungsten Carbide Fact

Tungsten carbide fact is created when tungsten and carbon are combined in equal amounts. In order to create tungsten carbide, the process has to be carried out at temperatures between 1,400 and 2,000 degrees centigrade. The resulting product, tungsten carbide, has an extremely high melting point of about 5,200 degrees Fahrenheit and a low electrical resistance, meaning it readily conducts electricity.

Describe of the product profile

Thickness, width, as well as Length and groovs shape can be various. If you have interest in purchasing our products, kindly please provide us the following necessary information for production:

- specific dimensions including length, width, and thickness;

- dimension tolerance if you have;

- surface condition: sintered blank or grinding;

- quantity;

- tungsten carbide grade or chemical composition

![]()

![]()

![]()

Any interested items please feel free to contact:

Contact:Tracy

Mob: +8615873380794

wechat:15873380794

WhatsApp: +8615873380794

Email: tracy@goldswordcarbide.com